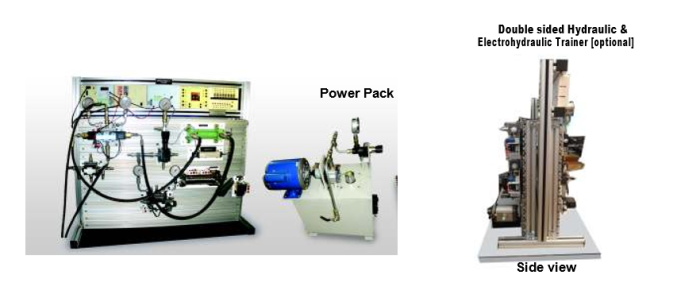

Electro Hydraulic with PLC

Product Overview:

This flexible training system is available in configurations—Electro-Hydraulic—with an optional integration of a Programmable Logic Controller (PLC). It features a durable experiment board made of an aluminum profile grooved plate (groove pitch: 25 mm), offering a sturdy and adaptable platform for practical learning. For added convenience, the setup can include three storage drawers and four caster wheels for smooth mobility. Circuit building is simplified with quick-release socket plug connections, streamlining setup and experimentation. Lightweight hydraulic components are easily mounted and repositioned using lever-operated molded adapters for quick and secure handling.

SALIENT FEATURES

- Choice of table top model Electro Hydraulic trainer (optionally PLC may be supplied).

- Use of aluminium profile grooved plate (CD= 25MM) experiment board. Optionally table with drawers (3 Nos.) to store components when not in use & 4 Nos. of caster wheels.

- Zero leakage flat quick release socket plug arrangement provided for building circuits, Lighter hydraulic components are mounted using lever operated moulded adapters for quick release & placement.

- List of components may be modified as per your requirement.

- Top electrical panel row exists in electro hydraulics / Pneumatic only

Hydraulic Subsystem

Sub-Plate & Pressure Elements

-

Oil Distribution Sub-Plate (1-station manifold) with 4 ports + 2 Gauge Ports

-

Equipped with Manual Quick Release Controls & Plugs

-

2× Glycerin-Filled Pressure Gauges (70 Bar)

-

Direction Control Valves:

-

4/2 Way Single Solenoid Valve (24VDC, Spring Return) – 1 No.

-

4/3 Way Double Solenoid Valve (24VDC, Spring Return) – 1 No.

-

Actuating Devices (Output)

-

Single Acting Cylinder: 40mm x 100mm Stroke with QR Adaptor – 1 No.

-

Double Acting Cylinder: 40mm x 100mm Stroke with In-Line Flow Control Valve & QR Sockets – 1 No.

Connections & Accessories

-

Flexible Hoses (R1 Type, 1/4" ID):

-

2 Nos. – 2000 mm

-

2 Nos. – 1500 mm

-

Ends: One straight, one 90°

-

-

Flat Type Quick Release:

-

Male Plugs – 20 Nos.

-

Female Sockets – 10 Nos.

-

-

T-Nuts with Star Knobs – 32 Nos.

Electrical & Control System

-

Electrical Cords:

-

Banana Patch Cords (4 mm):

-

1 m – 5 Nos.

-

500 mm – 5 Nos.

-

100 mm – 5 Nos.

-

-

-

Control Interface:

-

24VDC Power Supply Panel

-

8-Relay Interface Card (PLC Compatible, NO/NC Contacts)

-

Dual Timer with NO/NC Contacts

-

Optional Siemens PLC (12 Inputs + 8 Outputs) with CDP & Ladder Software

-

Mechanical & Structure

-

Aluminum Profile Rack (Tabletop Configuration)

-

Grooved T-Bolt Board (Pitch: 25 mm, Optional Double-Sided)

-

Board Dimensions: 1070 mm (L) × 70 mm (W) × 700 mm (H)

-

Reclining Positions: 0°, 20°, 30°

-

-

Overall Frame Size: 1165 mm (L) × 300 mm (W) × 800–990 mm (H)

-

Oil Tray: 1070 mm × 300 mm × 20 mm (Powder-Coated MS)

-

Weight:

-

Net: 70–75 kg

-

Gross: 85–90 kg

-

Experiments

A) Electric Control Based Experiments

-

Operation of Single Solenoid with Single Acting (S.A.) Cylinder

-

Single Solenoid + Limit Switch with S.A. Cylinder

-

Double Solenoid with Double Acting (D.A.) Cylinder

-

Double Solenoid + Limit Switch with D.A. Cylinder

-

Operation of Flow Control Check Valve

-

Junction-based fluid flow behavior

-

Push Button–Based Cylinder Extension

-

Signal Storage using Electrical Self-Locking (Momentary Switch/Logic Circuit)

-

Mechanical Locking using Momentary Switch Contacts

-

Electrical Locking & Signal Storage using Relay Contacts

-

Solenoid Actuation using Proximity Switch with D.A. Cylinder

B) PLC Control Based Experiments

-

Basic Cylinder In/Out Movement

-

Push-to-Extend, Push-to-Retract (D.A. Cylinder)

-

Cylinder with Delayed Return Function

-

Double Cylinder Synchronization